Volkswagen Tiguan Service and Repair Manual: Subframe, Servicing, from 05/28/2012

Front Bonded Rubber Bushing, Replacing

Special tools and workshop equipment required

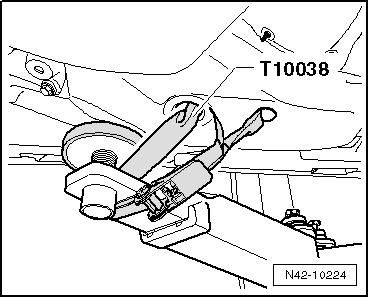

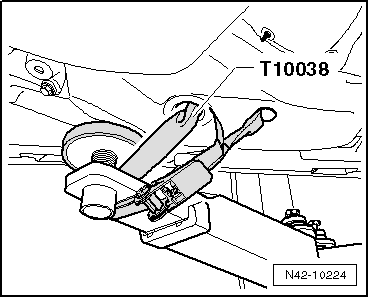

- Tensioning Strap -T10038-

- Hydraulic Press - Rear Subframe Bushing Tool Kit -T10263-

- Subframe Bushing Assembly Tool Kit -T10356-

- Engine and Gearbox Jack -VAS6931-

- Hydraulic Press -VAS6178- with Bearing Installer - Wheel Hub/Bearing Kit- Pressure Head -T10205/13-

- Pneumatic/Hydraulic Foot Pump -VAS6179-

- Bearing Installer - Wheel Hub/Bearing Kit -T10205-

Note

- If a bonded rubber bushing is faulty, then the bonded rubber bushing on the opposite side must also be replaced. Refer to the Parts Catalog for the allocation.

- Check the other bearing before switching out a defected bonded rubber bushing.

- If there are any tears or other visible damages, replace the bonded rubber bushing.

- In order to replace the rubber bonded bushing, the subframe must be lowered either at the front or at the rear. It is not necessary to remove the subframe.

- Identify mounting location to subframe before removing the bonded rubber bushing.

Pressing Out Bonded Rubber Bushing, Front

- Loosen the wheel bolts.

- Raise the vehicle.

- Remove the wheels.

- Remove the spring.

- Remove the rear muffler.

- Disconnect the electric connections between the rear axle and the body.

- Remove the stabilizer bar.

- Remove the tie rods.

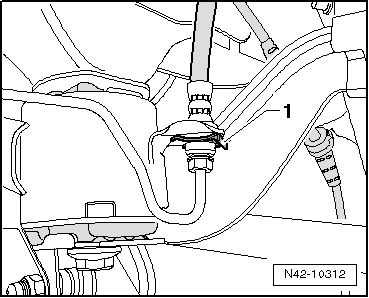

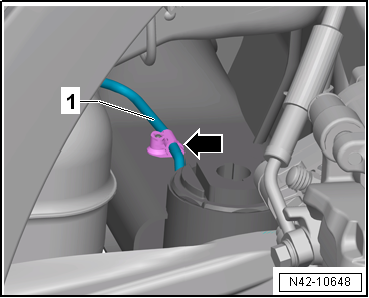

- Remove the clamps -1- on both sides of the vehicle.

Note

Do not disconnect the brake line.

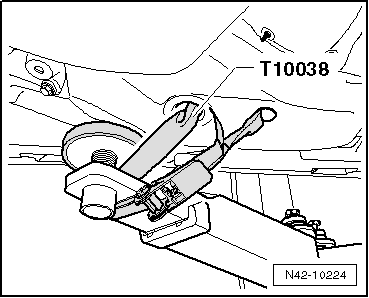

- Secure both sides of the vehicle on the hoist arms using Tensioning Straps -T10038-.

WARNING

The vehicle could slide off the hoist if it is not secured.

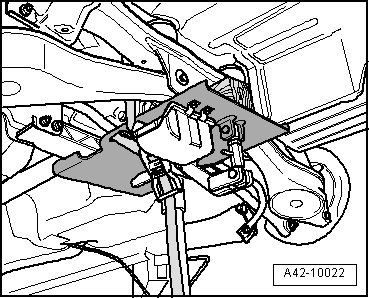

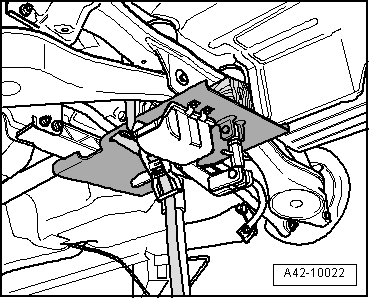

- Place the Engine and Gearbox Jack -VAS6931- with Universal Support Plate -VAG1359/2- below subframe and secure with strap.

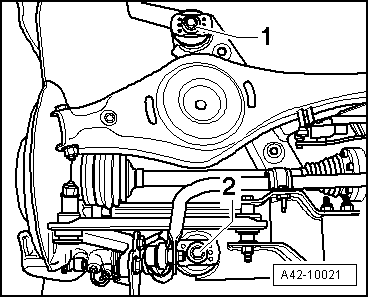

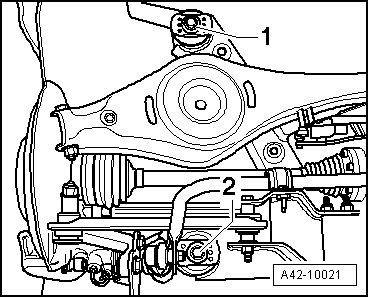

- Remove hex head bolt -1 or 2- on both sides.

Note

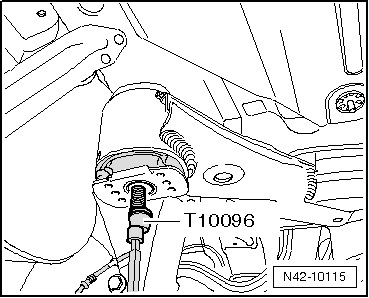

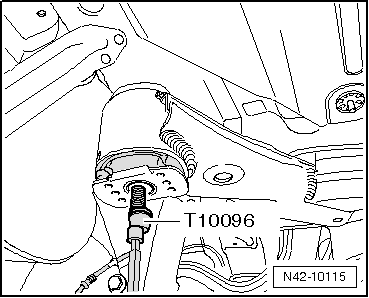

Only the left side of the vehicle is shown in the illustration.

To secure the subframe, Locating Pins -T10096- must be screwed in one after the other on both sides of the vehicle at positions -1 and 2-.

- Secure the position of the subframes using two Locating Pins -T10096- to 20 Nm.

Note

Locating Pins -T10096- may only be tightened to a maximum of 20 Nm, since otherwise the threads of the locating bolts will be damaged.

- Replace the bolts of the subframe one after the other on both sides using Locating Pins -T10096- and tighten them to 20 Nm.

The subframe position is now secured.

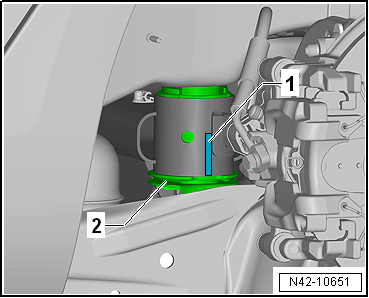

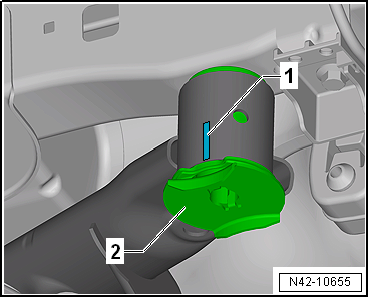

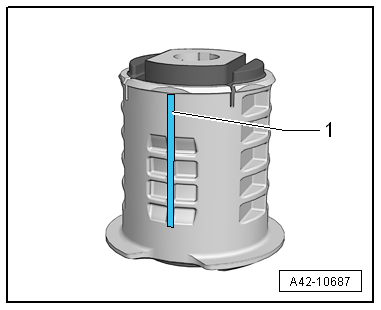

- Mark the installation location of the bonded rubber bushing on the subframe with a felt-tip pen -1-.

Note

Apply the mark -1- on the subframe in the middle of the recess on the bonded rubber mounting -2-.

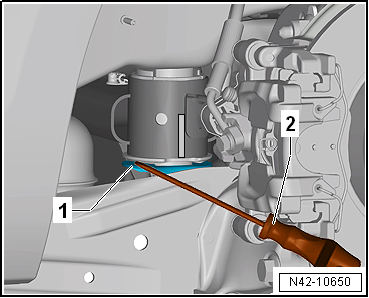

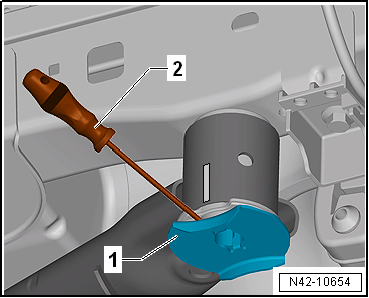

- Use a screwdriver -2- to pry off the anti-twist mechanism -1- near the bonded rubber bushing mounting retaining lugs.

- Lower the subframe approximately 100 mm using the Engine and Gearbox Jack -VAS6931-.

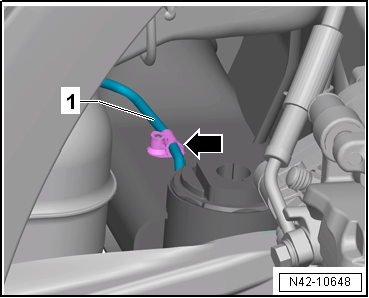

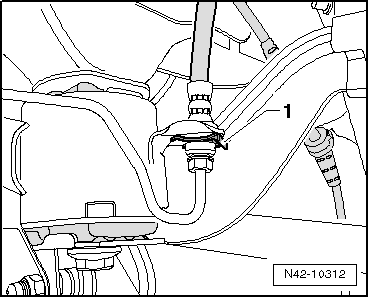

- Unclip the brake line -1- from the clip -arrow- on the left side.

Note

This will destroy the clip, so it will have to be replaced.

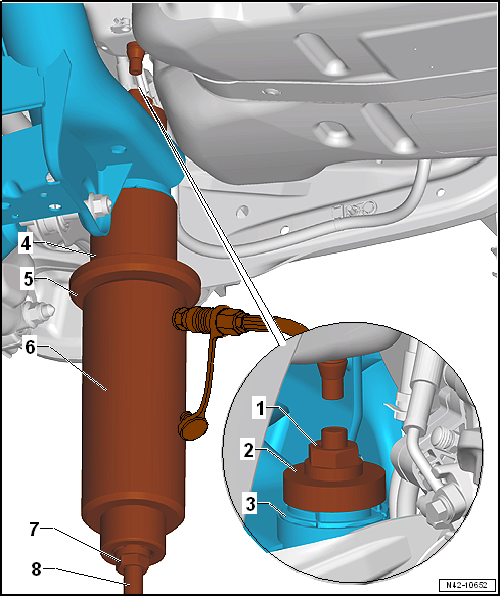

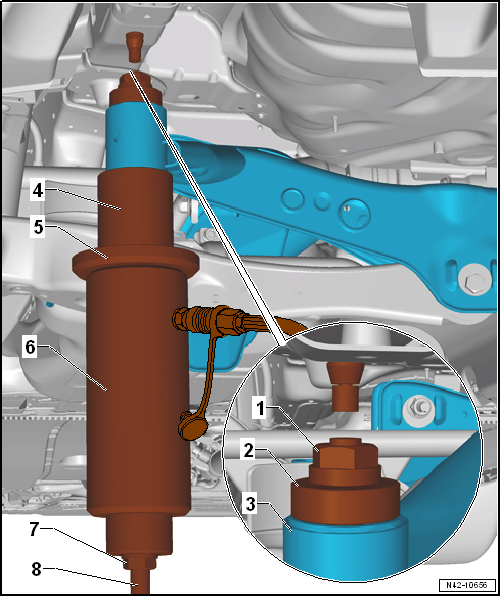

- Use the special tools as shown.

- Hydraulic Press - Rear Subframe Bushing Tool Kit - Nut -T10263/5-

- Subframe Bushing Assembly Tool Kit-Press Piece -T10356/1-

- Subframe

- Subframe Bushing Assembly Tool Kit-Pipe -T10356/2-, side with shoulder points to subframe

- Bearing Installer - Wheel Hub/Bearing Kit - Gripping Device -T10205/1-

- Hydraulic Press -VAS6178- with Bearing Installer - Wheel Hub/Bearing Kit- Pressure Head -T10205/13-

- Hydraulic Press - Rear Subframe Bushing Tool Kit - Nut -T10263/5-

- Hydraulic Press - Rear Subframe Bushing Tool Kit-Threaded Rod -T10263/4-

- Pretension special tools.

- Press out the bonded rubber bushing.

Note

- When removing the bonded rubber mounting, the bearing outer race is sheared off. There is a loud crack when this happens.

- After removing the bonded rubber bushing, it must be removed from the Tube -T10356/2- by tapping lightly with a hammer.

Press In on the Front Bonded Rubber Bushing

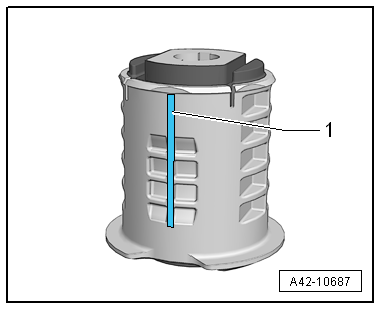

- Apply a line -1- on the vertical rib of the bonded rubber bushing to help mount.

- Apply mounting paste to the outer edge of the bonded rubber bushing.

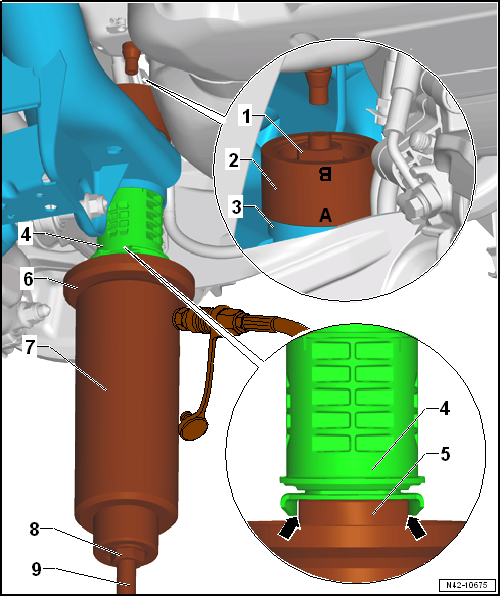

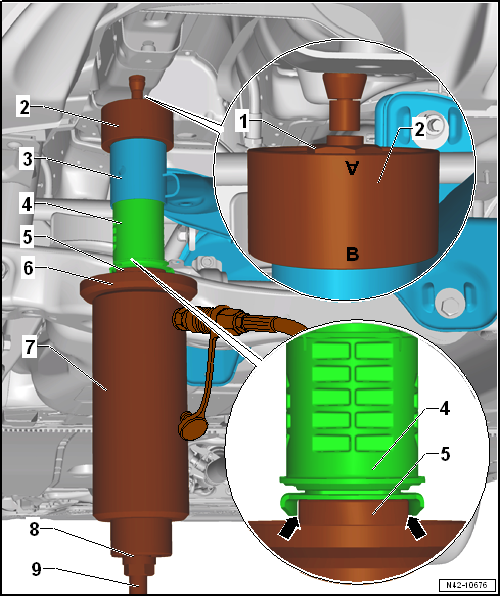

- Insert special tools with bonded rubber bushing into subframe as illustrated.

- Hydraulic Press - Rear Subframe Bushing Tool Kit - Nut -T10263/5-

- Subframe Bushing Assembly Tool Kit-Thrust piece -T10356/7- - the mark -A- points to the subframe

- Subframe

- Adjust the bonded rubber bushing to the marks (the marks need to align)

- Assembly Tool - Bushing -T10356/8- - the flattened sides need to fit into the cover of the bonded rubber bushing -arrows-.

- Bearing Installer - Wheel Hub/Bearing Kit - Gripping Device -T10205/1-

- Hydraulic Press -VAS6178- with Bearing Installer - Wheel Hub/Bearing Kit Pressure Head -T10205/13-

- Hydraulic Press - Rear Subframe Bushing Tool Kit - Nut -T10263/5-

- Hydraulic Press - Rear Subframe Bushing Tool Kit - Threaded Rod -T10263/4-

- Check the position of the bonded rubber bushing and, if necessary, align and pre-tighten special tools with bonded rubber bushing.

Note

- Make sure that the hose from the Hydraulic Press -VAS6178- to the Pneumatic/Hydraulic Foot Pump -VAS6179- runs between the trailing arm and the fuel tank when installed.

- Make sure that the bonded rubber bushing is not bent when installing. Otherwise the outer ring could become damaged.

- Operate the pump to press in the bonded rubber bushing until the shoulder is positioned on the subframe "without gap".

Install in reverse order of removal. Note the following:

Tightening Specifications

| Component | Tightening Specification |

Subframe to body

|

90 Nm +90º |

Rear Bonded Rubber Bushing, Replacing

Special tools and workshop equipment required

- Tensioning Strap -T10038-

- Hydraulic Press - Rear Subframe Bushing Tool Kit -T10263-

- Subframe Bushing Assembly Tool Kit -T10356-

- Engine and Gearbox Jack -VAS6931-

- Hydraulic Press -VAS6178- with Bearing Installer - Wheel Hub/Bearing Kit- Pressure Head -T10205/13-

- Pneumatic/Hydraulic Foot Pump -VAS6179-

- Bearing Installer - Wheel Hub/Bearing Kit -T10205-

Note

- If a bonded rubber bushing is faulty, then the bonded rubber bushing on the opposite side must also be replaced. Refer to the Parts Catalog for the allocation.

- Check the other bearing before switching out a defected bonded rubber bushing.

- If there are any tears or other visible damages, replace the bonded rubber bushing.

- In order to replace the rubber bonded bushing, the subframe must be lowered either at the front or at the rear. It is not necessary to remove the subframe.

- Identify mounting location to subframe before removing the bonded rubber bushing.

Pressing Out Rear Bonded Rubber Bushing

- Loosen the wheel bolts.

- Raise the vehicle.

- Remove the wheels.

- Remove the spring.

- Remove the rear muffler.

- Remove the clamps -1- on both sides of the vehicle.

Note

Do not disconnect the brake line.

- Secure both sides of the vehicle on the hoist arms using Tensioning Straps -T10038-.

WARNING

The vehicle could slide off the hoist if it is not secured.

- Place the Engine and Gearbox Jack -VAS6931- with Universal Support Plate -VAG1359/2- below subframe and secure with strap.

- Remove hex head bolt -1 or 2- on both sides.

Note

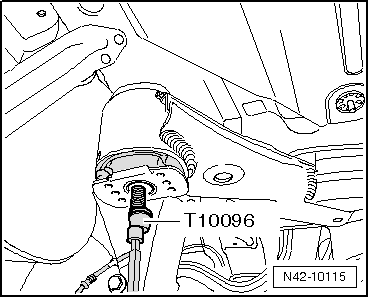

Only the left side of the vehicle is shown in the illustration.

To secure the subframe, Locating Pins -T10096- must be screwed in one after the other on both sides of the vehicle at positions -1 and 2-.

- Location position of subframe with Locating Pins -T10096-.

Note

Locating Pins -T10096- may only be tightened to a maximum of 20 Nm, since otherwise the threads of the locating bolts will be damaged.

- Replace the bolts of the subframe one after the other on both sides using Locating Pins -T10096- and tighten them to 20 Nm.

The subframe position is now secured.

- Mark the installation location of the bonded rubber bushing on the subframe with a felt-tip pen -1-.

Note

Apply the mark -1- on the subframe in the middle of the recess on the bonded rubber mounting -2-.

- Use a screwdriver -2- to pry off the anti-twist mechanism -1- near the bonded rubber bushing mounting retaining lugs.

- Lower the subframe approximately 100 mm using the Engine and Gearbox Jack -VAS6931-.

- Unclip the brake line -1- from the clip -arrow- on the left side.

Note

This will destroy the clip, so it will have to be replaced.

- Use the special tools as shown.

- Hydraulic Press - Rear Subframe Bushing Tool Kit - Nut -T10263/5-

- Subframe Bushing Assembly Tool Kit - Thrust Piece -T10356/5-

- Subframe

- Subframe Bushing Assembly Tool Kit - Tube -T10356/6-, side with offset points to subframe

- Bearing Installer - Wheel Hub/Bearing Kit - Gripping Device -T10205/1-

- Hydraulic Press -VAS6178- with Bearing Installer - Wheel Hub/Bearing Kit Pressure Head -T10205/13-

- Hydraulic Press - Rear Subframe Bushing Tool Kit - Nut -T10263/5-

- Hydraulic Press - Rear Subframe Bushing Tool Kit-Threaded Rod -T10263/4-

- Pretension special tools.

- Press out the bonded rubber bushing.

Note

- When removing the bonded rubber mounting, the bearing outer race is sheared off. There is a loud crack when this happens.

- After removing the bonded rubber bushing, it must be removed from the Subframe Bushing Assembly Tool Kit - Tube -T10356/6- by tapping lightly with a hammer.

Press In the Rear Bonded Rubber Bushing

- Apply a line -1- on the vertical rib of the bonded rubber bushing to help mount.

- Apply mounting paste to the outer edge of the bonded rubber bushing.

- Insert special tools with bonded rubber bushing into subframe as illustrated.

- Hydraulic Press - Rear Subframe Bushing Tool Kit - Nut -T10263/5-

- Subframe Bushing Assembly Tool Kit - Bushing -T10356/7- - the marking -B- points to the subframe

- Subframe

- Adjust the bonded rubber bushing to the marks (the marks need to align)

- Subframe Bushing Assembly Tool Kit - Bushing -T10356/8- - the flattened sides need to fit into the cover of the bonded rubber bushing -arrows-.

- Bearing Installer - Wheel Hub/Bearing Kit - 1 -T10205/1-

- Hydraulic Press -VAS6178- with Bearing Installer - Wheel Hub/Bearing Kit Pressure Head -T10205/13-

- Hydraulic Press - Rear Subframe Bushing Tool Kit - Nut -T10263/5-

- Hydraulic Press - Rear Subframe Bushing Tool Kit - Threaded Rod -T10263/4-

- Check the position of the bonded rubber bushing and, if necessary, align and pre-tighten special tools with bonded rubber bushing.

Note

Make sure that the bonded rubber bushing is not bent when installing. Otherwise the outer ring could become damaged.

- Operate the pump to press in the bonded rubber bushing until the shoulder is positioned on the subframe "without gap".

Install in reverse order of removal. Note the following:

Tightening Specifications

| Component | Tightening Specification |

Subframe to body

|

90 Nm +90º |

Subframe, Servicing, through 05/2012

Subframe, Servicing, through 05/2012

Special tools and workshop equipment required

Tensioning Strap -T10038-

Locating Pins -T10096-

Hydraulic Press - Rear Subframe Bushing Tool Kit -T10263-

Engine and Gearbox Jack -VAS6931-

Hydraul ...

Transverse Link, Tie Rod, AWD

Transverse Link, Tie Rod, AWD

Overview - Transverse Link, Tie Rod, AWD

The -arrow- points in the direction of travel.

Eccentric Bolt

Perform a vehicle alignment after loosening.

Do not turn more than 90º right or left (t ...

See More:

Volkswagen Tiguan Service and Repair Manual > Rear Suspension: Transverse Links and Tie Rods, through MY 2010, FWD

Overview - Transverse Links and Tie Rods, through MY 2010, FWD

Eccentric Bolt

For camber setting

Perform a vehicle alignment after loosening.

Nut

95 Nm

Always replace if removed

M12 x 1.5

Self-locking

Always tighten the threaded connections in curb weight position.

Eccen ...

Volkswagen Tiguan Owners Manual

Volkswagen Tiguan Service and Repair Manual

- Body exterior

- Body Interior

- General Paint Information

- Paint

- Brake System

- Suspension, Wheels, Steering

- Wheel and Tire Guide

- Towing Guide

- Wheel and Tire Guide General Information

- Communication

- Electrical Equipment General Information

- Electrical Equipment from 06/2011

- Heating, Ventilation and Air Conditioning

- Refrigerant R134a Servicing

- 6-Speed Manual Transmission 02Q, OBB, and OFB